Corte láser

Las tecnologías de corte con láser (o corte con haz láser) son un grupo de procesos que permiten moldear piezas sin tener contacto con el material inicial. En líneas muy generales éstas tecnologías funcionan dirigiendo una columna de haz de luz de una sola longitud de onda por una boquilla hasta un material laminar, una combinación de calor y presión en un área muy pequeña permiten que el material se derrita, queme, vaporice o sea apartado por una corriente de aire o gas dejando así acabados muy limpios en el corte o grabado.

Las tecnologías de corte con láser (o corte con haz láser) son un grupo de procesos que permiten moldear piezas sin tener contacto con el material inicial. En líneas muy generales éstas tecnologías funcionan dirigiendo una columna de haz de luz de una sola longitud de onda por una boquilla hasta un material laminar, una combinación de calor y presión en un área muy pequeña permiten que el material se derrita, queme, vaporice o sea apartado por una corriente de aire o gas dejando así acabados muy limpios en el corte o grabado.

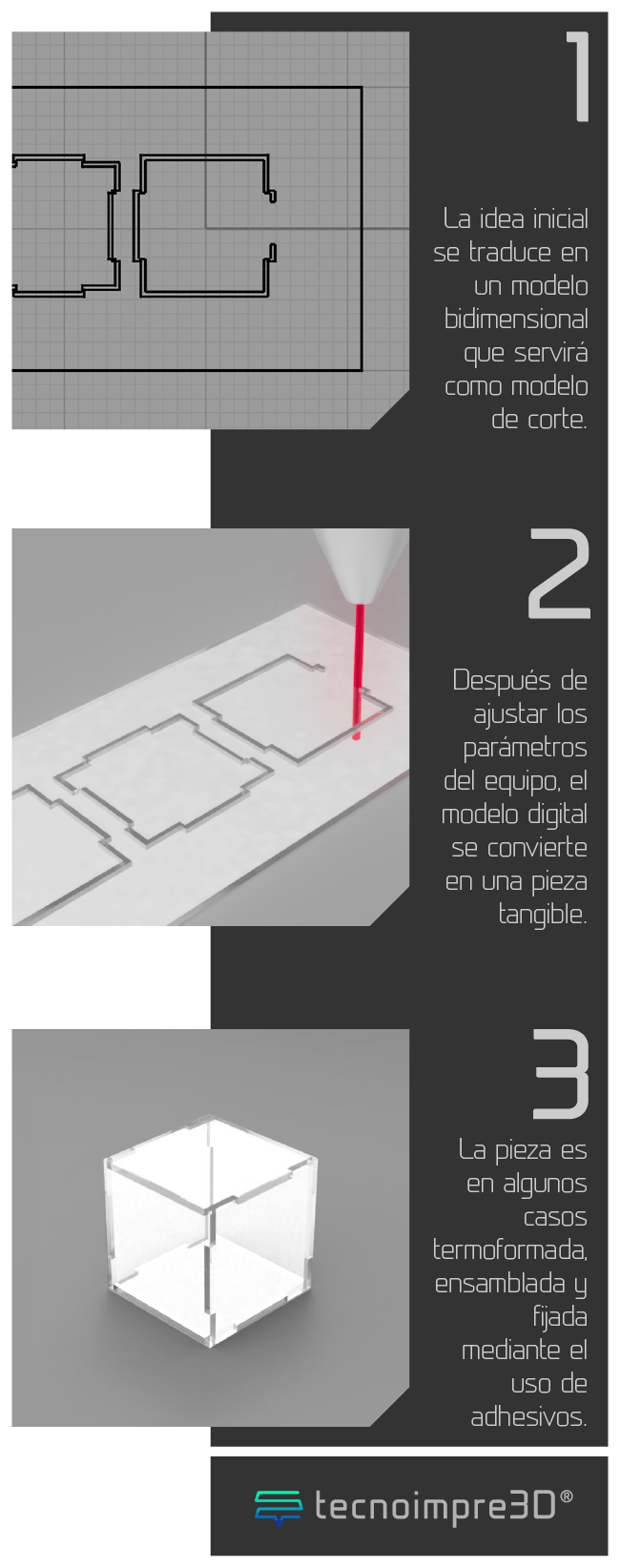

La boquilla que dirige el haz láser es guiada por métodos de control numérico de alta precisión que siguen como referencia un modelo digital normalmente bidimensional, ésta precisión y control permite crear piezas muy complejas de geometría intrincada que no podrían ser obtenidas a través de métodos tradicionales. Esta tecnología puede aplicarse a distintos metales y plásticos adaptando el tipo de haz, onda y gas aplicado en la boquilla.

En Tecnoimpre 3D nos especializamos en tecnologías de corte y grabado con haz láser en materiales laminares plásticos de distintos calibres, acabados y colores. La precisión de esta tecnología es un elemento clave para la interacción entre piezas creadas con ésta y otros métodos de prototipado rápido. Al tratarse de materiales termoplásticos, en Tecnoimpre 3D ofrecemos también el termoformado de piezas laminares, un método ideal para formar volúmenes a partir de piezas cortadas y grabadas con haz láser.

Alta precisión:

La calidad del acabado de los cantos y la precisión de ésta tecnología es incomparable, esto se debe a que el elemento de corte (haz láser) nunca entra en contacto con el material cortado, por lo tanto (y a diferencia de métodos de desbaste) el sistema de corte no se desgasta ni crea variaciones por uso. Con tecnologías de corte láser por ejemplo se podrían cortar orificios rectangulares o circulares de hasta 1 milímetro de diámetro, una hazaña muy difícil de conseguir con otros métodos de prototipado.

Fidelidad y control:

Una de las ventajas de ésta tecnología es que gracias a su precisión y control las piezas resultantes son idénticas a lo que se proyecta en la pantalla antes de cortar, es por esto que esta tecnología es normalmente utilizada para cortes y grabados de identificadores de marcas. Tal control permite también aprovechar al máximo el material, pues cada centímetro puede ser aprovechado.

Energía concentrada:

En algunos métodos de corte por desbaste la temperatura del material se eleva tanto que deforma la lámina inicial pandeándola y obteniendo resultados indeseados. El corte y grabado con haz láser concentra toda su energía en un área muy pequeña, de esta manera no afecta la temperatura de toda la pieza y por lo tanto no la deforma.