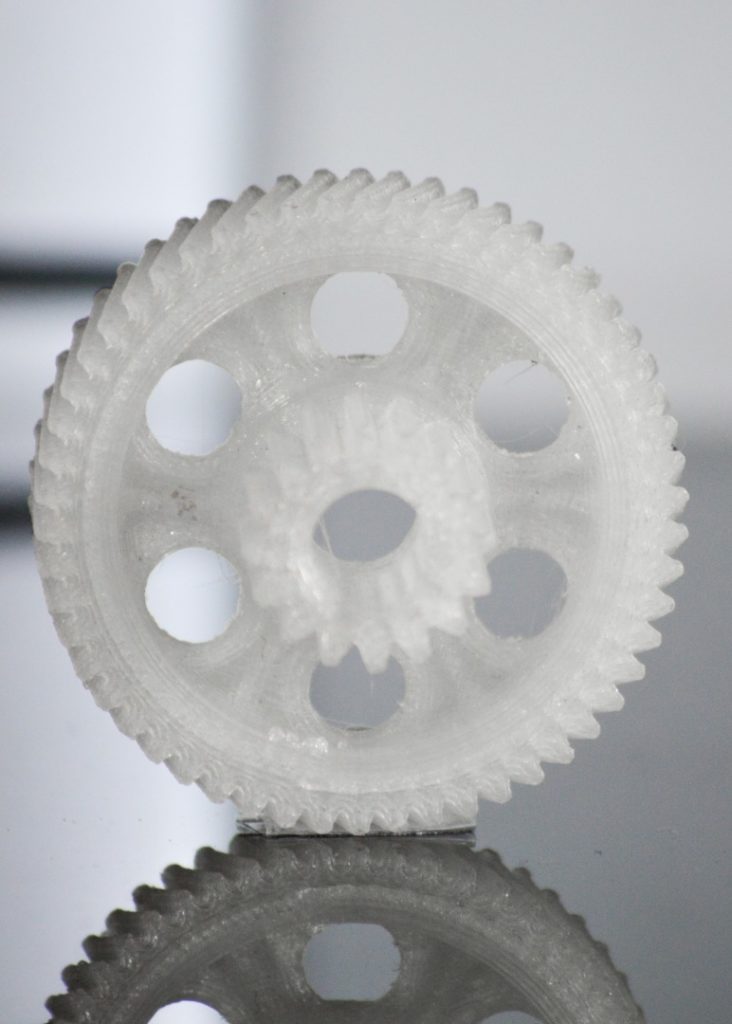

Diseño 3D

Nuestro equipo de diseñadores está preparado para asumir cualquier proyecto en el área Ingenieril u orgánica.

Nuestro equipo de diseñadores está preparado para asumir cualquier proyecto en el área Ingenieril u orgánica.

Contamos con un equipo de profesionales integrado por ingenieros y diseñadores industriales dirigidos por líderes de proyecto con experiencia.

Nuestro servicio de diseño está dirigido a…

- Compañías: Desde el año 2013 hemos desarrollado más de 400 proyectos para compañías tales como Procter and Gamble, Laboratorios Vita, Cisa, CAVIM, Trenzas Carrizal, entre otras. Diseños tan diversos como envases, dispositivos de pruebas en laboratorio, moldes para alimentos.

- Particulares: Atendemos las necesidades de nuestros clientes particulares para contribuir en su ascenso profesional, orientándolos en sus ideas para lograr desarrollar esa pieza o producto que requieren

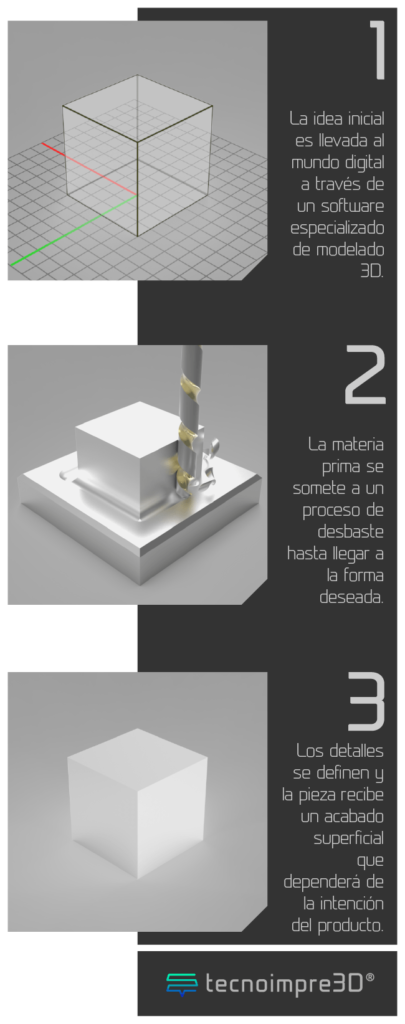

Así nace un proyecto

- Todo empieza con una visita a su compañía para recabar la información que requerimos.

- Analizamos la información para determinar la forma de abordar el proyecto, establecer fases y tiempo de desarrollo.

- Enviando la cotización y una vez aprobada la misma proceder a darle vida a su pieza hasta probarla mediante el prototipo de la misma.

- Al ser certificada la pieza o dispositivo por parte del cliente procederemos a elaborar el plano y entregarlos junto al archivo 3D.

Cerramos de esta manera, el proyecto y almacenando la información del mismo en un lugar seguro.